Study on Proteolytic Potential of Buffalo Milk Using Lactococcus Lactis Ssp. Cremoris and Lactococcus Lactis Ssp. Lactis-Juniper Publishers

Journal of Dairy & Veterinary Sciences- Juniper Publishers

Introduction

Buffalo milk contains all the nutrients in higher

proportions than cow milk as per the nutrient components. The

compositional differences between buffalo and cow milk are reflected on

their physico-chemical properties. Milk from buffalo preferred for

preparing dairy products of western and traditional (indigenous) type

and nutritionally superior. Buffalo milk contains less cholesterol

(total cholesterol 275 mg and free cholesterol 212mg per 100g of fat) in

compared to cow milk (total cholesterol 330 mg and free cholesterol

280mg per 100g of fat) and more tocopherol (334.21|ig per kg for buffalo

and 312.3|ig per kg of cow milk). Due to high peroxidase activity,

buffalo milk can be preserved naturally for a longer period. Buffalo

milk contains more calcium, better calcium: phosphorous ratio and less

sodium and potassium than cow milk which makes it a better nutritional

supplement for infants.

Due to growth requirements, dairy starter cultures

have developed highly sophisticated proteolytic system that capable of

break down milk proteins, mainly a1 and p-caseins. The proteolytic

structure of lactic acid bacteria (LAB) and their activities in dairy

products including yogurt and cheese have been studied extensively [1-5].

Lactococcus lactis has two subspecies with few phenotype and genotype differences, Lactococcus lactis ssp. lactis and ssp. cremoris, where subsp. lactis is preferred for making soft cheese while subsp. Cremoris is for hard cheese.

Materials and Methods

Periodical evaluation of fermented buffalo milk

Fresh buffalo milk was skimmed to bring the fat

contents to below 0.5% using cream separator. The samples were heated to

boil at least for 5min to inactivate/kill the inherent microbial

population present in milk. Then Lactococcus lactis ssp. cremoris and Lactococcus lactis ssp. lactis

cultures were inoculated @ 1% and after proper mixing, the samples were

inoculated at 30 °C .The samples were drawn at 0, 2, 4, 6, 8, 10, 12

hours and were subjected to analysis for change in pH.

Bacterial cultures and their propagation

Glass ampoules containing Lyophilized powder of Lactococcus lactis ssp. cremoris NCDC 81 and Lactococcus lactis ssp. lactis

NCDC 88 were obtained from the NCDC (National Collection of Dairy

Cultures) Dairy Microbiology Division ICAR-National Dairy Research

Institute, Karnal (INDIA). The organisms were stored at 4 °C. The

propagation for each strain was performed according to Donker et al., [1]

with slight modification. Sterile 5ml aliquots of reconstituted sterile

skim milk (RSM) (Himedia Laboratories) were inoculated with each strain

individually and incubated at 30 °C for 24h in BOD incubator. After

incubation, the pre-inoculated cultures were prepared by transferring

loop full of activated culture to 10ml aliquots of litmus milk (Himedia

Laboratories) to determine the activation of culture activity by

observing change in color of litmus milk after 24 hour of inoculation Figure 1. The skim milk and litmus milk were autoclaved following the standard procedure (121°C for 15min @15lbs).

pH measurement of milk samples:

The pH of samples was measured by using combined

glass electrode of Milkoscan at camel milk research laboratory, ICAR-

NRC on Camel, Bikaner.

Result and Discussion

Change in pH during hydrolysis:

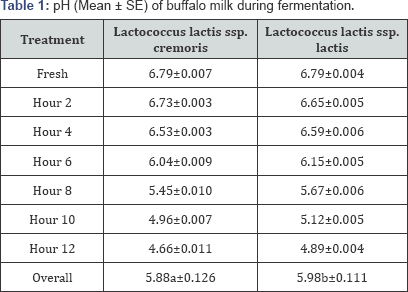

Note - Means bearing different superscripts within a row differ significantly

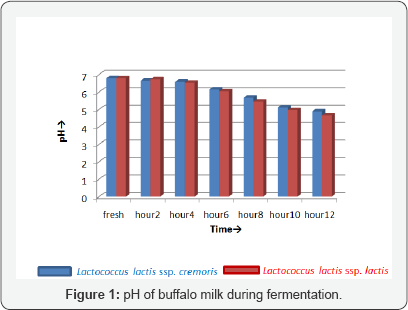

The data related to pH of buffalo milk has been shown in Table 1 .The pH of fresh milk was found to be 6.79±0.004 for Lactococcus lactis ssp. cremoris and 6.79±0.007 for Lactococcus lactis ssp. lactis before inoculation of treated bacteria.

The value of pH was dropped significantly as the

fermentation hour were increased and at 12 hour of fermentation and it

was observed to be 4.89±0.004 and 4.66±0.011 for Lactococcus lactis ssp. cremoris and Lactococcus lactis ssp. lactis respectively whereas the overall pH was 5.98±0.111 and 5.88±0.126 for Lactococcus lactis ssp. cremoris and Lactococcus lactis ssp. lactis respectively. The pH value demonstrated in Table 1 reveals that the rate of decrement was higher in samples, which are fermented with Lactococcus lactis ssp. cremoris comparing with Lactococcus lactis ssp. lactis, in buffalo milk samples. [6,7].

Process of fermentation is affected by several

factors including the structure of the protein, temperature, enzyme/

protein ratio, enzyme concentration and pH. In the present study, almost

linear drop in pH was observed during the fermentation process in

buffalo milk samples. The release of protons (H+ ion) and/or production

of acidic amino acids into the surrounding medium results in reduction

in the pH of the reaction mixture.

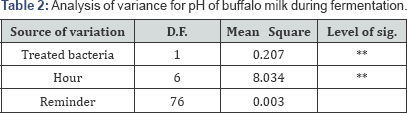

** = Significant at 1% (P<0.01).

The statistical analysis of data as shown in Table 2,

revealed that there was a highly significant (P<0.01) decrease in

the pH value of buffalo milk samples with advancement of fermentation

hours as well as between the treated bacteria that is Lactococcus lactis ssp. cremoris and Lactococcus lactis ssp. lactis. [8,9].

To know more about Journal of Dairy & Veterinary Sciences:

https://juniperpublishers.com/jdvs/index.php

https://juniperpublishers.com/jdvs/index.php

To know more about Open Access Publishers: Juniper Publishers

Comments

Post a Comment